Floating Concrete Pontoons

Perfect For

• Full- Service Marinas

• Expansions and Renovations

• Waterfront Access for Hotels and Restaurants

• Water Sports

• Bridges and Gangways

• Private Docks

• Commercial ( Fishing ports, Ferries )

• Security & Military ports

• Expansions and Renovations

• Waterfront Access for Hotels and Restaurants

• Water Sports

• Bridges and Gangways

• Private Docks

• Commercial ( Fishing ports, Ferries )

• Security & Military ports

Engineering Specifications

The water is a highly dynamic environment. Each concrete pontoons is designed precisely to fit the needs and conditions of its application, including dimensions, freeboard, joint strength and joint gap

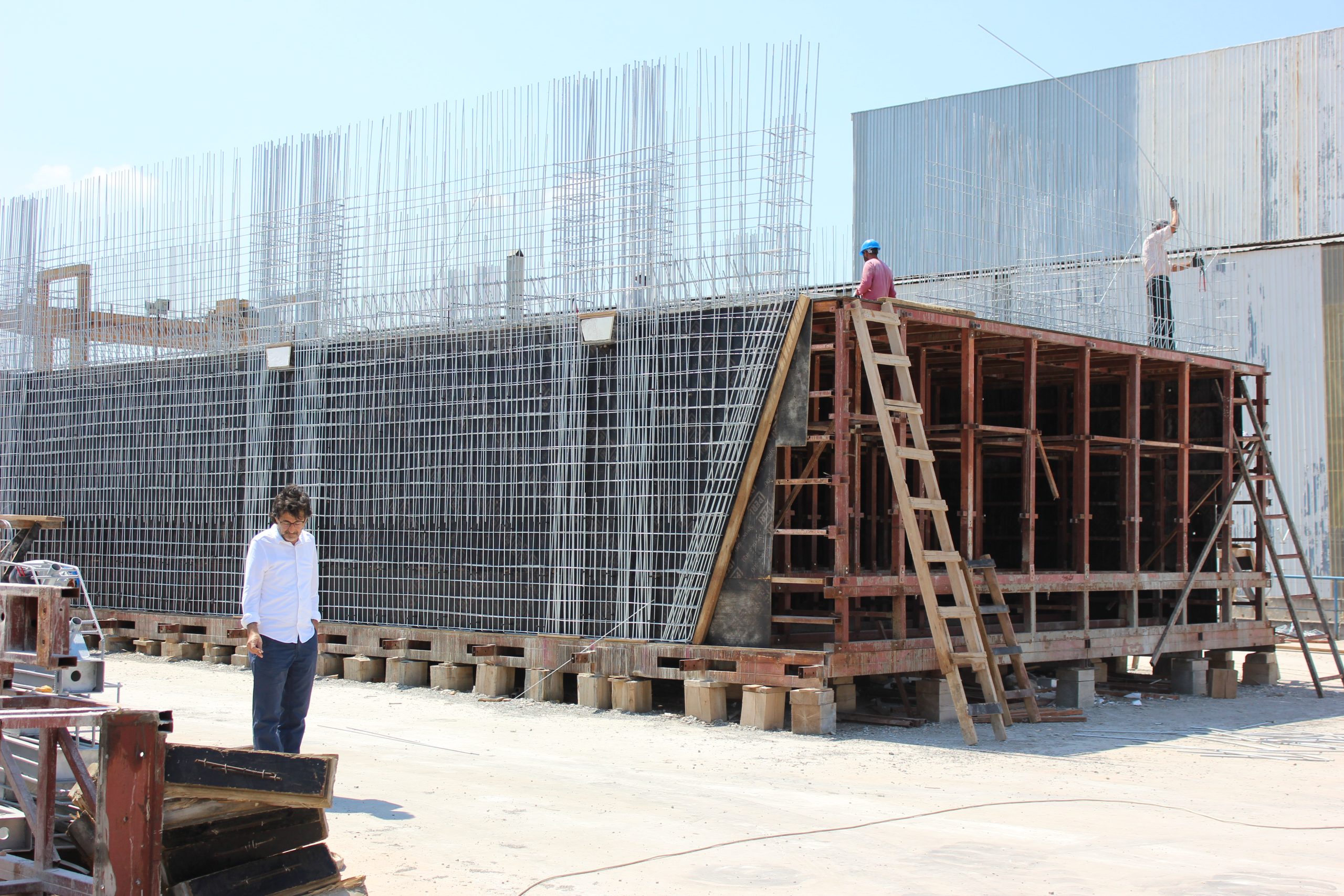

Structure

Molded from C40/50 Concrete.

Internal structure is reinforced by hot-dip galvanized S420-S500 steel framework.

Main volume is filled with 16kg/m EPS Styrofoam.

Fenders can me made of wood or rubber.

Internal structure is reinforced by hot-dip galvanized S420-S500 steel framework.

Main volume is filled with 16kg/m EPS Styrofoam.

Fenders can me made of wood or rubber.

Decking Options

The walkable surface is built-in to the components-barefoot friendly, non-skid surface. However, additional decking options like aluminum, pressure-treated wood, composite, pavers and concrete are available.

Several color options

Can be mounted with clips (removable) or rivets (permanent).

Can be ordered without decking, compatible with all decking suppliers.

Can be ordered without decking, compatible with all decking suppliers.

Buoyancy

Each unit is self-buoyant and load bearing. Safe for walking or driving vehicles.

Advantages

Concrete Pontoons are a perfect solution where poor foundation conditions prohibit the use of seafloor supported systems.

Deep Water

In water depths in excess of 19 ft, floating pontoons are much more economical than seafloor supported systems.

Environmentally Friendly

Near zero environmental impact, minimum interference with water circulation and wildlife.

Configuration

Modular floating units can be configured to form both straight lines and arcs. Easy to configure and re-arranged without the need for additional parts.

Service Ducts

Service ducts are molded into the structure with removable top covers.